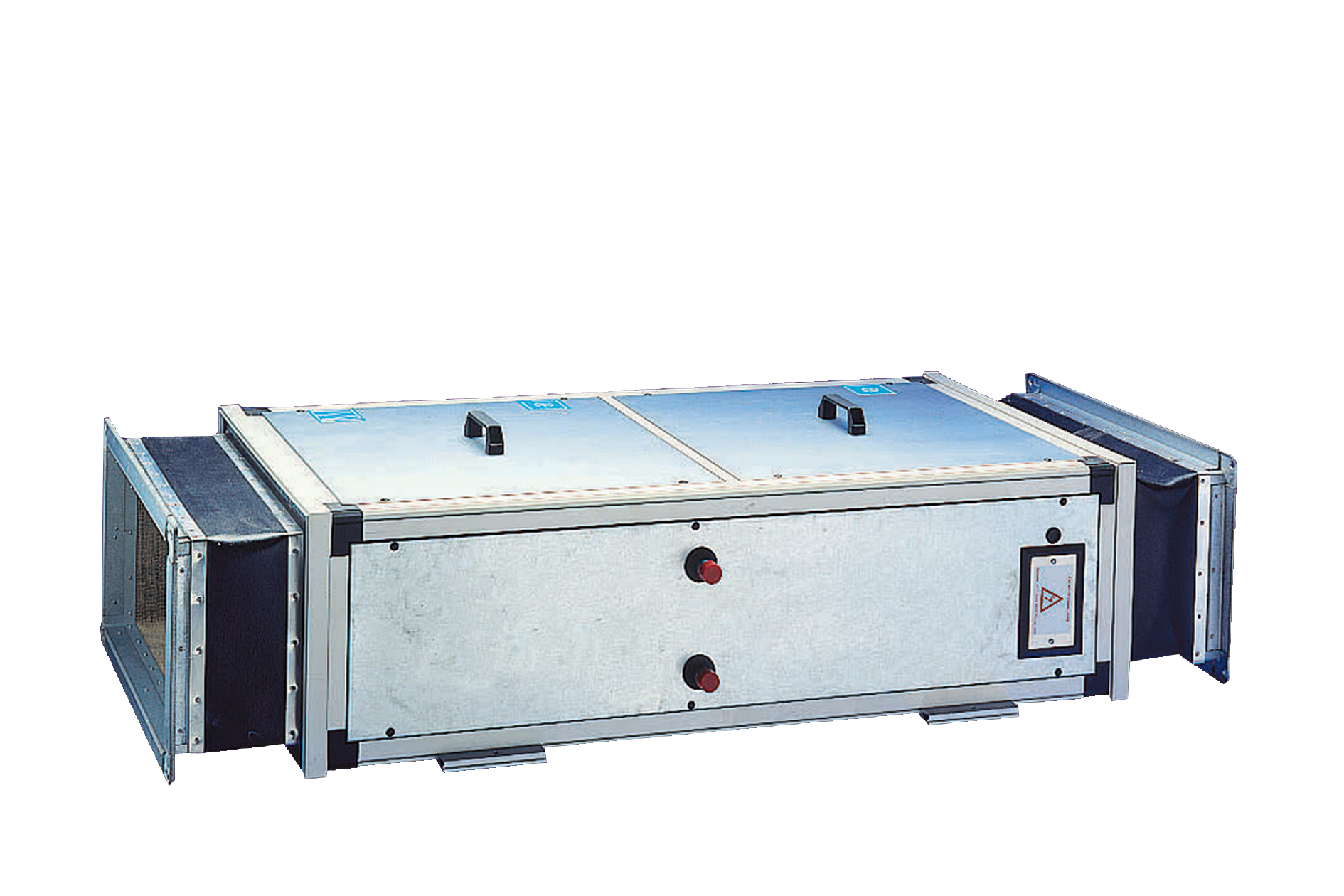

Slimline Range (SL)

At a Glance:

Designed specifically for applications with limited available height such as ceiling voids.

The casing comprises of an AA25 anodised aluminium frame.

All panels are sealed by a purpose designed leak seal gasket fully retained into the aluminium framework.

Backward curved energy efficient EC motor impellers

The units are suitable for internal mounting only.

FAQs Answered:

Construction Parameters according to EN1886

Performance range up to 0.9m³/s

EC Energy efficient motors

Standard Thermal Overload Protection (S.T.O.P.)

Anodised aluminium pentapost frame

Double skinned panels

Low profile direct drive units

Internal mounting only

Integral controls

Designed specifically for applications with limited available height such as ceiling voids. Access (to be specified at time of ordering) can be from above or below with heater and motor connections on the left or right hand side.

The casing comprises of an AA25 anodised aluminium frame with high density glass reinforced nylon corners and double skinned panels of 0.7mm galvanised steel enclosing 25mm of 60kg/m³ mineral fibre insulation. All panels are retained by proprietary fasteners. All panels are sealed by a purpose designed leak seal gasket fully retained into the aluminium framework.

Slimline Unit - Duties from 0.05m³/s to 0.92m³/s

Low profile direct drive units with backward curved centrifugal fans designed for applications where restricted height is a problem and top or bottom access is required. There are two sizes of unit available. All units are powered by single phase energy efficient EC motors complete with integral control electronics to accept a 0-10V control input. The standard unit comprises; inlet flexible connector, EU5 bag filter, l.p.h.w. or electric heater, direct drive fan and outlet flexible connector. The unit is suitable for internal mounting only. Electric heater versions also include a simple heater control unit enabling the air off temperature to be controlled to an internally adjustable set point. External temperature set point controls are available as an option.

Specification

Direct Drive backward curved centrifugal impellers factory matched to an EC (electronically commutated) external rotor motor and statically and dynamically balanced to ISO 1940 as a complete assembly. The external rotor motors have sealed for life ball bearings. The motors are suitable for ambient temperatures of up to 40°C and atmospheres up to 95% R.H.

Flexible Connectors

The Flexible Connectors are manufactured from Revertex JPT 20 with ductmate flanges to DW142.

Bag Filters

Bag Filters are manufactured from fire retardant synthetic material with galvanised steel frames. The filter grade is EU5 to Eurovent 4/5.

LPHW Heater Batteries

L.P.H.W. Heater Batteries are constructed from copper tube, mechanically bonded to aluminium fins with the complete assembly housed in a galvanised steel casing. The coil headers and return bends are totally enclosed within the air handling unit casing. Flow and return connections are located on the same side of the unit and have male B.S.P. thread. L.P.H.W. Heater Batteries are pressure tested under water to 250p.s.i.

Electric Heater Batteries

Electric Heater Battery elements are constructed from Nichrome 5 spiral resistance wire surrounded by magnesium oxide powder and sheathed in stainless steel. The elements are carried on a galvanised steel frame. All electric heaters incorporate a thermal cut out device.

DIMENSIONS:

| Unit | A | B | C | D | E | F | G |

| SL6-22 | 1560 | 660 | 600 | 360 | 300 | 758 | 220 |

| SL8-31 | 1560 | 810 | 750 | 360 | 300 | 758 | 220 |

| --- | |||||||

| Stock Ref No. | L | AL | C | D | Approx Weight kg | ||

| 1200 | 900 | 360 | 660 | 29 | |||

| 1200 | 900 | 360 | 660 | 29 | |||

| SL6-22 | 1500 | 1200 | 360 | 660 | 33 | ||

| 1800 | 1500 | 360 | 660 | 39 | |||

| 1200 | 900 | 360 | 810 | 37 | |||

| SL8-31 | 1500 | 1200 | 360 | 810 | 42 | ||

| 1800 | 1500 | 360 | 810 | 48 | |||

| Attenuator | |||||||

| --- | |||||||

| Unit | Inlet Damper Stock Ref No | C | D | Approx Weight kg | |||

| SL6-22 | 57CD-66 | 360 | 660 | 6 | |||

| SL8-31 | 57CD-81 | 360 | 810 | 7 |

PDF DOWNLOADS:

Raadpleeg de tab Downloads voor technische informatie

ESTIMATED RUNNING COSTS

Calculate estimated running costs for this product using the tool below.

For average costs*, leave the default values in place or enter your own figures in the boxes to recalculate.

Where a product has multi speeds, a typical installation has been used for the below calculations. *Running cost does not include the use of the heater on the heater model

Based on the inputted figures, estimated running costs would be:

Overview

Designed specifically for applications with limited available height such as ceiling voids. Access (to be specified at time of ordering) can be from above or below with heater and motor connections on the left or right hand side.

The casing comprises of an AA25 anodised aluminium frame with high density glass reinforced nylon corners and double skinned panels of 0.7mm galvanised steel enclosing 25mm of 60kg/m³ mineral fibre insulation. All panels are retained by proprietary fasteners. All panels are sealed by a purpose designed leak seal gasket fully retained into the aluminium framework.

Slimline Unit - Duties from 0.05m³/s to 0.92m³/s

Low profile direct drive units with backward curved centrifugal fans designed for applications where restricted height is a problem and top or bottom access is required. There are two sizes of unit available. All units are powered by single phase energy efficient EC motors complete with integral control electronics to accept a 0-10V control input. The standard unit comprises; inlet flexible connector, EU5 bag filter, l.p.h.w. or electric heater, direct drive fan and outlet flexible connector. The unit is suitable for internal mounting only. Electric heater versions also include a simple heater control unit enabling the air off temperature to be controlled to an internally adjustable set point. External temperature set point controls are available as an option.

Specification

Direct Drive backward curved centrifugal impellers factory matched to an EC (electronically commutated) external rotor motor and statically and dynamically balanced to ISO 1940 as a complete assembly. The external rotor motors have sealed for life ball bearings. The motors are suitable for ambient temperatures of up to 40°C and atmospheres up to 95% R.H.

Flexible Connectors

The Flexible Connectors are manufactured from Revertex JPT 20 with ductmate flanges to DW142.

Bag Filters

Bag Filters are manufactured from fire retardant synthetic material with galvanised steel frames. The filter grade is EU5 to Eurovent 4/5.

LPHW Heater Batteries

L.P.H.W. Heater Batteries are constructed from copper tube, mechanically bonded to aluminium fins with the complete assembly housed in a galvanised steel casing. The coil headers and return bends are totally enclosed within the air handling unit casing. Flow and return connections are located on the same side of the unit and have male B.S.P. thread. L.P.H.W. Heater Batteries are pressure tested under water to 250p.s.i.

Electric Heater Batteries

Electric Heater Battery elements are constructed from Nichrome 5 spiral resistance wire surrounded by magnesium oxide powder and sheathed in stainless steel. The elements are carried on a galvanised steel frame. All electric heaters incorporate a thermal cut out device.

Technical

DIMENSIONS:

| Unit | A | B | C | D | E | F | G |

| SL6-22 | 1560 | 660 | 600 | 360 | 300 | 758 | 220 |

| SL8-31 | 1560 | 810 | 750 | 360 | 300 | 758 | 220 |

| --- | |||||||

| Stock Ref No. | L | AL | C | D | Approx Weight kg | ||

| 1200 | 900 | 360 | 660 | 29 | |||

| 1200 | 900 | 360 | 660 | 29 | |||

| SL6-22 | 1500 | 1200 | 360 | 660 | 33 | ||

| 1800 | 1500 | 360 | 660 | 39 | |||

| 1200 | 900 | 360 | 810 | 37 | |||

| SL8-31 | 1500 | 1200 | 360 | 810 | 42 | ||

| 1800 | 1500 | 360 | 810 | 48 | |||

| Attenuator | |||||||

| --- | |||||||

| Unit | Inlet Damper Stock Ref No | C | D | Approx Weight kg | |||

| SL6-22 | 57CD-66 | 360 | 660 | 6 | |||

| SL8-31 | 57CD-81 | 360 | 810 | 7 |